In the cacophony of environmental challenges, one resounding solution echoes with promise: Plastic Pyrolysis. This transformative process holds the key to turning the tide on the rampant issue of plastic pollution, offering a beacon of hope in our quest for a cleaner and greener planet.

Plastic Predicament: A Global Menace

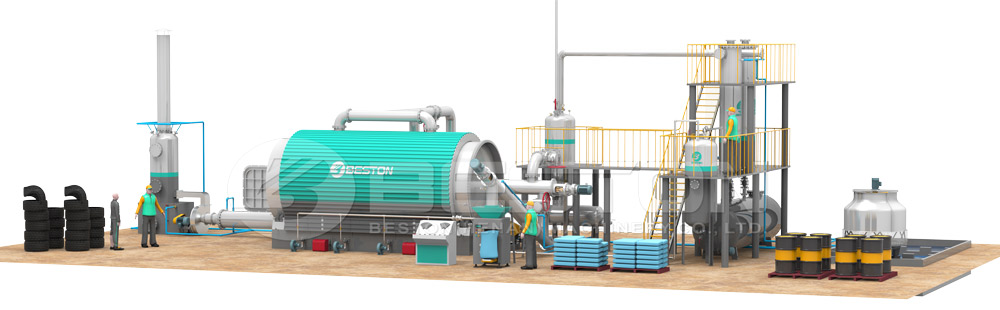

Plastic, once hailed as a modern marvel, has now become an ecological pariah. The oceans choke on plastic debris, landfills burgeon with non-biodegradable waste, and ecosystems bear the brunt of our convenience-driven plastic consumption. The urgency to address this crisis is palpable, and plastic pyrolysis machine emerges as the vanguards in this environmental revolution.

The Pyrolysis Paradigm: Breaking Down Plastics

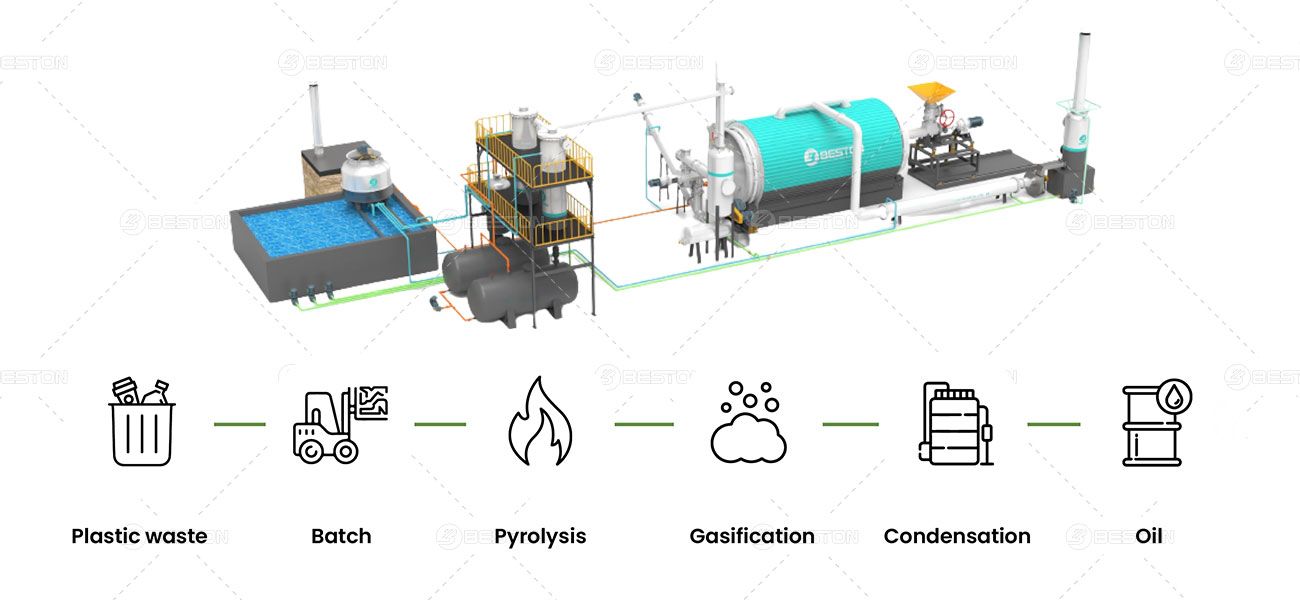

Enter the realm of plastic pyrolysis, a process that defies the conventional narrative of plastic disposal. It involves subjecting plastic waste to high temperatures in the absence of oxygen, triggering a molecular metamorphosis. The result is a spectrum of valuable byproducts, heralding the redemption of plastic from the clutches of pollution.

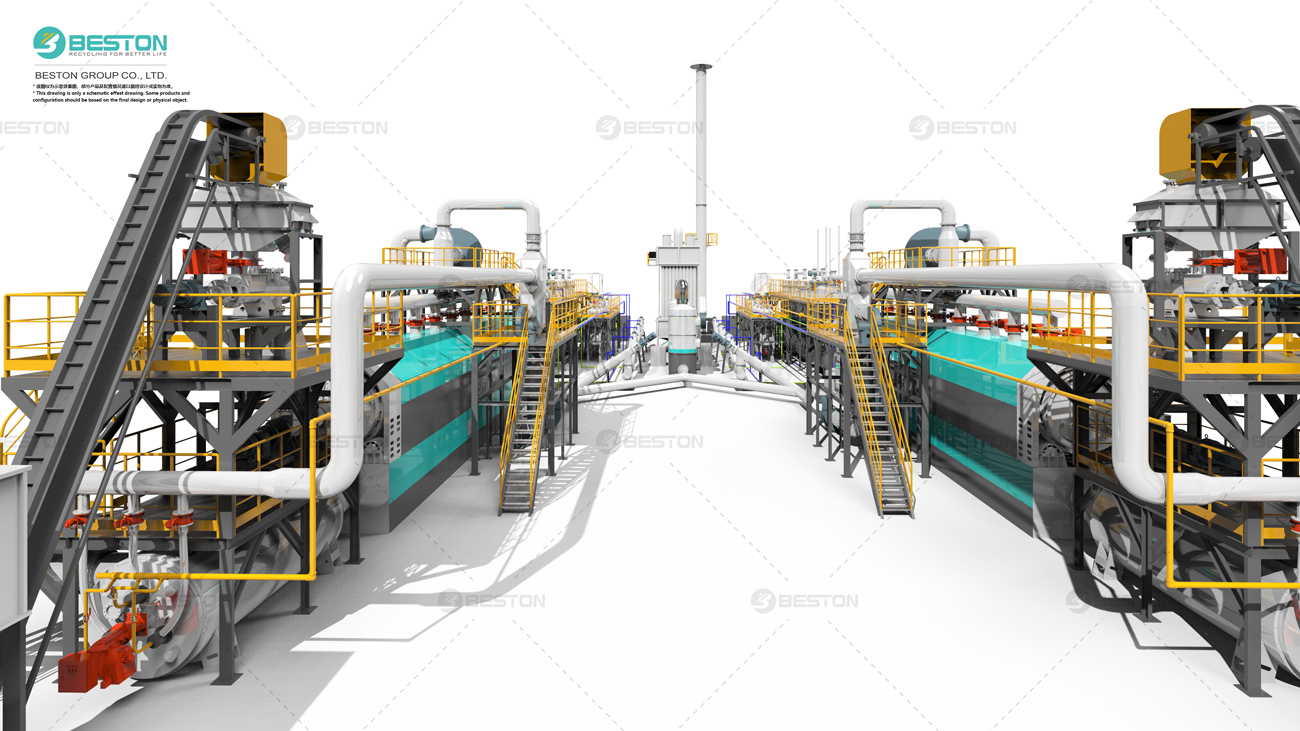

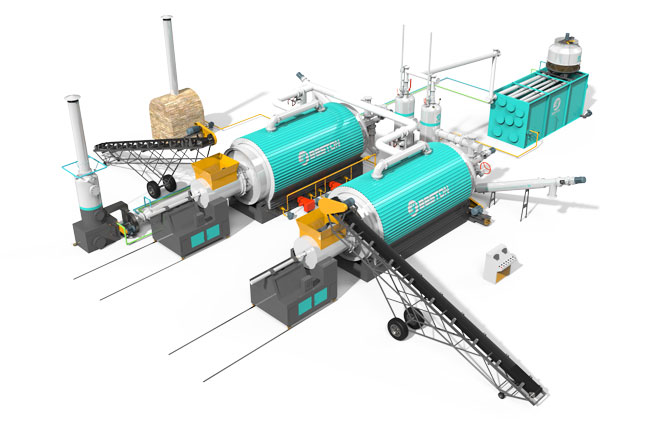

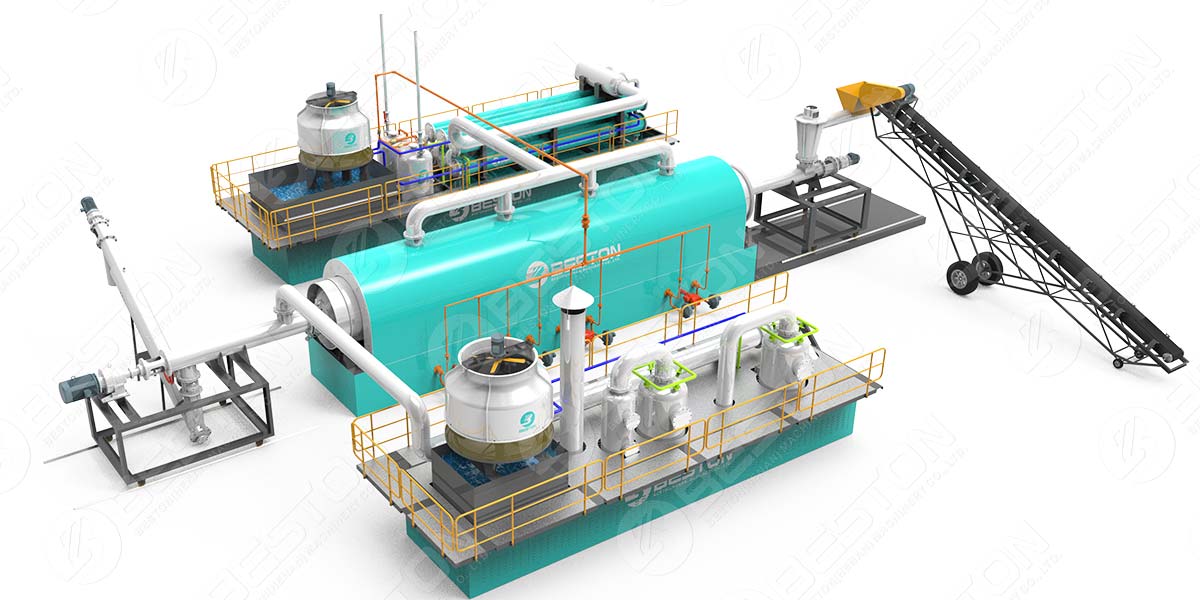

The Dance of Transformation: How Pyrolysis Works

In the fiery crucible of a plastic pyrolysis plant, plastics undergo a dance of transformation. The intense heat prompts the breakdown of complex polymer chains, yielding a rich concoction of pyrolysis oil, syngas, and carbon black. This alchemical process not only diverts plastics from landfills but also repurposes them into valuable resources.

Pyrolysis Oil: Liquid Gold from Plastic Rubbish

Amidst the crackling heat, pyrolysis oil emerges as the liquid gold of the process. This versatile substance finds applications in fuel production, paving the way for a circular economy where plastic waste becomes a feedstock for energy production.

Syngas: Fueling Sustainable Energy

As the plastic molecules undergo a thermodynamic metamorphosis, syngas dances into existence. This gaseous blend of hydrogen and carbon monoxide holds the potential to fuel a myriad of applications, from electricity generation to industrial processes, creating a sustainable energy source from discarded plastic.

Carbon Black: The Resilient Residue

From the ashes rises carbon black, a resilient residue with applications ranging from ink production to reinforcing rubber. The reincarnation of plastic waste into valuable commodities underscores the transformative power of plastic pyrolysis.

The Environmental Ballet: Pyrolysis’s Ecological Impact

Beyond the confines of the plastic pyrolysis plant, the ripple effect on the environment is profound. By diverting plastics from conventional disposal routes, this process mitigates the strain on landfills and slashes the carbon footprint associated with traditional plastic manufacturing.

Landfill Liberation: A Second Chance for Plastics

As plastics find redemption in the pyrolytic crucible, landfills breathe a sigh of relief. The relentless influx of non-biodegradable waste is curtailed, offering a second chance for plastics to serve a purpose beyond their initial use.

Carbon Footprint Slash: Paving the Green Path

Traditional plastic manufacturing leaves an indelible carbon footprint. Plastic pyrolysis, on the other hand, disrupts this pattern by repurposing existing plastic, significantly reducing the environmental toll associated with raw material extraction and production processes.

Global Implications: Pyrolysis as a Catalyst for Change

The adoption of plastic oil machine reverberates on a global scale, transcending borders in the fight against plastic pollution. Governments, industries, and environmental advocates converge in recognizing the potential of this revolutionary process as a catalyst for change.

Legislative Momentum: Paving the Regulatory Path

In the wake of plastic pollution awareness, legislative bodies are beginning to champion the cause of plastic pyrolysis. Regulatory frameworks are evolving to incentivize the adoption of this technology, heralding a new era where responsible plastic disposal is a shared responsibility.

Industry Integration: Shaping Sustainable Practices

Industries, too, are embracing the paradigm shift. The integration of plastic to fuel machine into manufacturing processes signifies a commitment to sustainable practices, showcasing that environmental responsibility can coexist with industrial progress.

The Road Ahead: Pyrolysis’s Ongoing Evolution

As we stand at the cusp of a plastic revolution, the journey of plastic pyrolysis is far from over. Ongoing research and technological advancements promise to refine the process, making it even more efficient and accessible on a global scale.

Technological Frontiers: Innovating the Pyrolytic Landscape

The landscape of plastic pyrolysis is a canvas waiting for technological pioneers. Innovations in reactor design, feedstock variety, and process optimization continue to shape the trajectory of this transformative technology, propelling us closer to a plastic-free future.