Most transport equipment, whether it is passenger cars or trucks, require rubber tyres for their smooth travel. These tyres have treads that enable the tyres to grip the road for safe movement. These treads get gradually worn out,and render the surface of the tyres smooth and likely to skid as they have lost their gripping power. They then have to be discarded, and find their way to landfills where they remain and create an environmental hazard. Technology has now come up with solutions that enable this rubber to be burned in fully automatic pyrolysis plant that converts the tyres into carbon black, an industrially useful product, and other gases and oil that have other uses. This reduces waste going into landfills.

There are many types of pyrolysis plants but the one that is most useful is the fully continuous tyre pyrolysis plant that will work without interruption and do so for several years. In this process of pyrolysis, the organic material in the tyres decomposes, chemically and physically, at very high temperatures that can be as high as 430 degrees Centigrade. This is done in the absence of oxygen and under pressure. As a result of this pyrolysis, the rubber in the waste tyres undergoes changes in both its physical and chemical composition, and the process is irreversible. What results is the rubber being converted to carbon, oil, gas, and ash. More information on waste tyre pyrolysis plant.

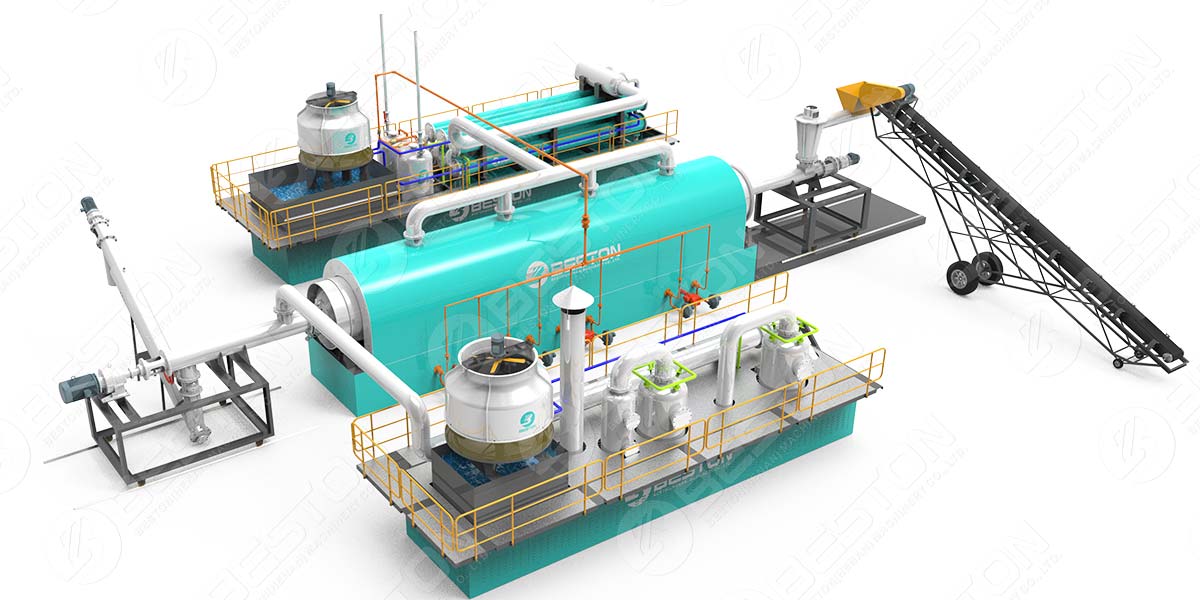

All this process of pyrolysis takes place in a reactor where some fuel is used to heat the rubber. This heating first produces oil gas that again requires to be condensed and liquefied till it forms oil that is then led to a tank. Some of the gas remains uncondensed, and this can be led back into the reactor to act as fuel for further burning of the rubber. This helps to save fuel costs for running the pyrolysis plant.

The raw material used in a pyrolysis plant can be rubber of any kind besides tyres. It is customary to shred the tyres in to smaller pieces, as this increases the surface area of the rubber that enable it to better gather the heat. A shredder will be an essential part of a fully continuous tyre pyrolysis plant. The shredded pieces are anywhere between 3 to 5 cm, and from the shredder go into a feeding system that directs the rubber to the reactor. Here is where the shredded rubber is burnt using initially any fuel like wood, gas, or coal. Once the temperature in the reactor reaches 300 degrees Centigrade, the rubber starts to break up into oil gas.

This continuous plant will have a three stage condensing system where the gas is led to, and requires to be cooled by water by water that circulates through the condenser. The water gets heated and is led into cooling towers that bring down the temperature of the water and permits it to be reused. Any gas that is not condensed is led back into the reactor to act as fuel.

Carbon black is also produced as a residue of the rubber and this plant will have a carbon discharge system that allows the carbon to be discharged separately to be made into carbon black balls that can then be sold. Continuous waste tyre recycling plant has internal rotating systems to enable the cotinuous operation.