Introduction

In the realm of outdoor cooking and heating, the choice between burning charcoal and wood has long been a subject of debate. Both fuels offer distinct advantages and drawbacks, but charcoal often emerges as the preferred option for discerning enthusiasts. Delving deeper into the nuances of this decision unveils a myriad of factors that influence the choice between charcoal and wood combustion.

The Charcoal Advantage: Efficiency and Consistency

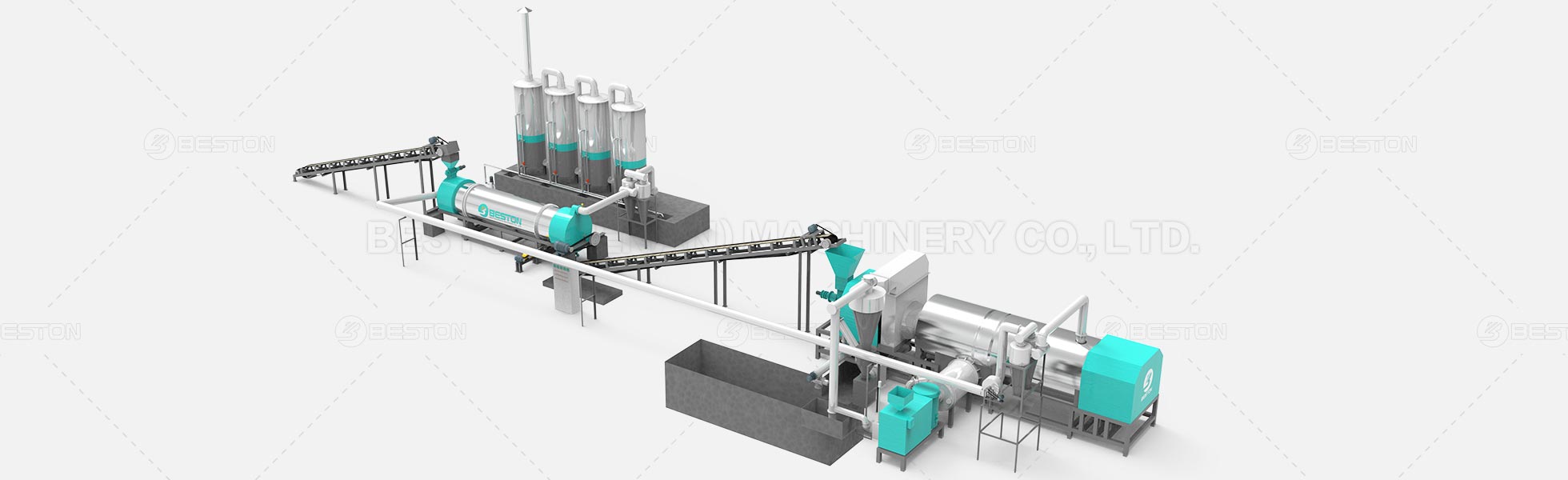

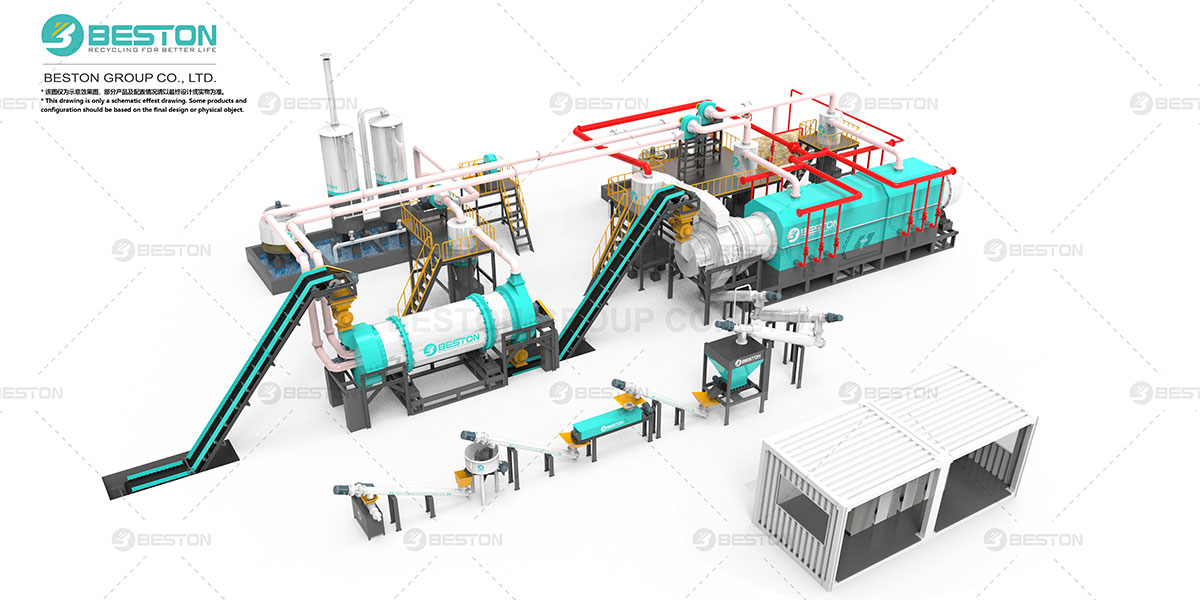

Charcoal, derived from the pyrolysis of wood or other organic materials, boasts several advantages over raw wood when used as a fuel source. One of the primary benefits is its enhanced energy density and efficiency. Through the process of pyrolysis, wood is transformed into charcoal, resulting in a fuel with higher carbon content and lower moisture content compared to raw wood. This higher carbon concentration translates to a more efficient and consistent heat output during combustion, making charcoal with charcoal making machine an ideal choice for applications where precise temperature control is essential, such as grilling and smoking.

Environmental Considerations: Cleaner Burning and Reduced Emissions

Another compelling reason to opt for charcoal over wood is its environmental impact. When burned, charcoal produces fewer emissions and pollutants compared to raw wood combustion. This is due to the absence of moisture and impurities in charcoal, which results in a cleaner and more complete combustion process. Additionally, charcoal combustion typically generates less smoke and particulate matter, reducing air pollution and minimizing the risk of respiratory irritation. For eco-conscious individuals and organizations, choosing charcoal as a fuel source aligns with efforts to reduce carbon footprint and promote sustainable practices.

Convenience and Versatility: Storage and Transport

From a practical standpoint, charcoal offers distinct advantages in terms of storage, transport, and convenience. Unlike bulky and cumbersome wood logs, charcoal is lightweight, compact, and easily stackable, making it easier to store and transport in large quantities. Additionally, charcoal’s uniform shape and size facilitate more consistent and predictable combustion characteristics, allowing for greater control over cooking and heating processes. Whether for backyard barbecues, camping trips, or outdoor events, the portability and versatility of charcoal make it a preferred fuel choice for individuals seeking convenience without compromising on performance. Get high quality charcoal manufacturing machine here.

Flavor and Aroma: Enhancing Culinary Delights

One of the most celebrated aspects of charcoal combustion is its ability to impart distinctive flavor and aroma to grilled and smoked foods. Unlike wood, which can introduce a range of flavors depending on species and moisture content, charcoal imparts a clean, neutral flavor profile that allows the natural tastes of food to shine through. This neutrality makes charcoal a versatile fuel choice for a wide range of culinary applications, from searing steaks to slow-roasting vegetables. Additionally, the absence of aromatic compounds present in some types of wood minimizes the risk of off-flavors or overpowering smoke taste, ensuring a harmonious culinary experience for chefs and diners alike. Check biochar production equipment here.

Economic Considerations: Cost and Accessibility

While charcoal offers numerous benefits in terms of efficiency, cleanliness, and flavor, it is essential to consider the economic factors that influence fuel choice. In many regions, charcoal is readily available at affordable prices, making it a cost-effective option for consumers seeking value without sacrificing quality. Additionally, the widespread availability of charcoal briquettes and lump charcoal products further enhances accessibility and convenience for consumers. Compared to wood, which may require seasoning and preparation before use, charcoal offers a hassle-free alternative that is ready to use straight out of the bag.

Conclusion: Making an Informed Choice

In the ongoing debate between charcoal and wood as fuel sources for outdoor cooking and heating, the advantages of charcoal are compelling and diverse. From its superior efficiency and consistency to its cleaner burning properties and culinary benefits, charcoal offers a multifaceted solution for discerning consumers. By considering factors such as environmental impact, convenience, flavor, and cost, individuals can make informed decisions that align with their preferences, priorities, and values. Whether grilling in the backyard or embarking on a wilderness adventure, the choice to burn charcoal instead of wood represents a commitment to quality, sustainability, and culinary excellence. Find charcoal solution from Beston Group.