In the quest for sustainable and eco-friendly energy alternatives, charcoal produced from biomass emerges as a standout solution that balances environmental stewardship with economic feasibility. Unlike traditional fossil fuels or even conventional wood charcoal, biomass charcoal offers a renewable, less polluting source of energy. This comprehensive guide delves into the multifaceted world of charcoal derived from biomass by charcoal making equipment, exploring its production, benefits, applications, challenges, and future prospects.

Introduction to Charcoal from Biomass

Charcoal is a lightweight, black residue, consisting of carbon and any remaining ash, obtained by removing water and other volatile constituents from plant materials. Historically, charcoal has been produced from wood, but the focus has shifted towards using biomass – organic material coming from plants and animals – to produce what is known as “biomass charcoal” or “biochar.” The switch to biomass as a feedstock is driven by the need to utilize waste materials and reduce reliance on wood, thereby preventing deforestation and contributing to a more circular economy.

The Production Process

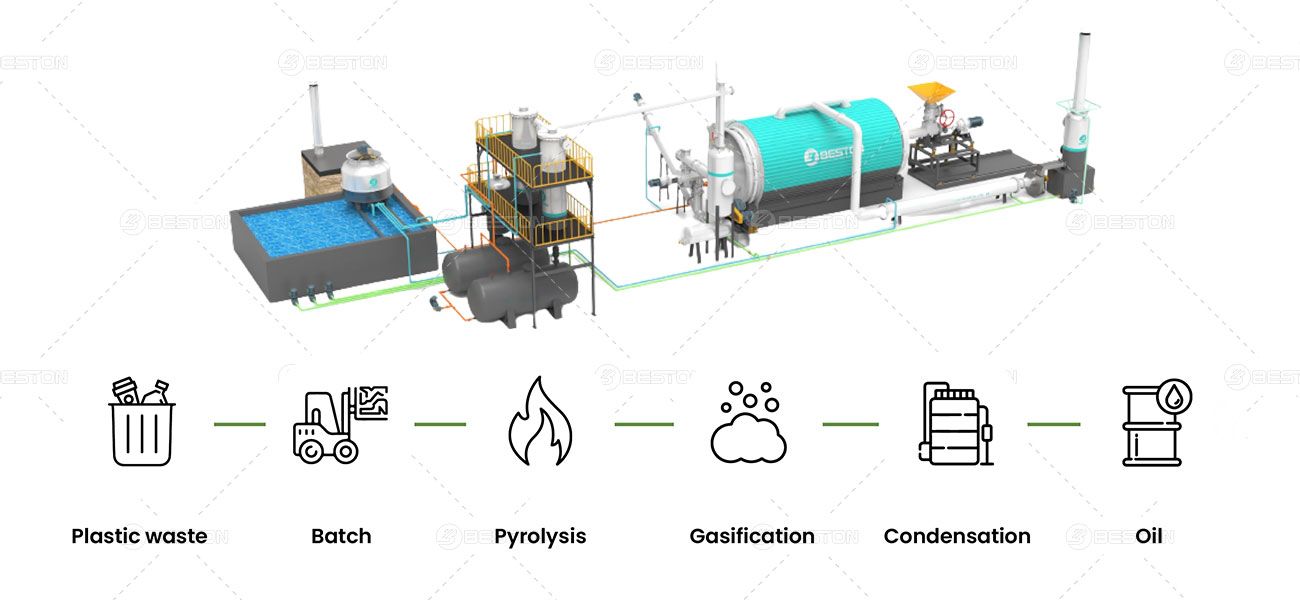

Pyrolysis

The most common method for producing biomass charcoal is pyrolysis – the thermal decomposition of materials at elevated temperatures in the absence of oxygen. This process results in the production of charcoal (solid), bio-oil (liquid), and syngas (gas). The specific conditions under which pyrolysis occurs, such as temperature, heating rate, and the time, significantly influence the quantity and quality of the charcoal produced.

Gasification

Another method is gasification, which partially oxidizes biomass at high temperatures, producing a syngas composed of hydrogen, carbon monoxide, and a small amount of charcoal. Though not primarily aimed at producing charcoal, the process does yield it as a by-product, with the main focus being on generating a clean, combustible gas.

Benefits of Biomass Charcoal

Environmental Advantages

The production and use of charcoal from biomass have several environmental benefits. It offers a carbon-neutral or even potentially carbon-negative energy option. When biomass decomposes naturally or is burned directly, it releases the carbon it absorbed during its growth back into the atmosphere. However, converting it into charcoal sequesters carbon, preventing its immediate release and thus reducing greenhouse gas emissions. If you wanna see more information, view https://bestonmachinery.com/charcoal-briquette-making-machine/.

Waste Management

Utilizing agricultural residues, food waste, or other organic waste materials to produce charcoal helps in managing waste effectively. It not only provides a way to dispose of such waste but also adds value to it, turning what would be pollutants into useful products.

Soil Amendment

Biochar, a specific type of biomass charcoal produced under certain conditions, can improve soil health. When added to soil, it enhances water retention, nutrient availability, and microbial activity, leading to increased agricultural productivity.

Applications of Biomass Charcoal

Energy Source

Biomass charcoal serves as a cleaner alternative to wood charcoal and fossil fuels for cooking and heating, especially in developing countries. Its higher energy density and lower smoke emissions make it a preferable choice for both household and industrial applications.

In Industry

Beyond its use as fuel, biomass charcoal finds applications in various industries. For example, it’s used in metal smelting as a reducing agent, in chemical industries as a feedstock, and even in the food industry for smoking meats due to its unique flavor-enhancing properties.

Environmental Remediation

The adsorptive properties of certain types of biomass charcoal, especially biochar, allow it to capture and hold contaminants from water and soil, offering a promising solution for environmental remediation projects.

Challenges and Solutions

Despite its potential, the widespread adoption of biomass charcoal faces several challenges. These include:

Technological and Economic Barriers

The initial setup cost for pyrolysis or gasification systems can be high, making it difficult for small-scale producers to adopt these technologies. Moreover, the variability in biomass feedstock requires adaptable technology to efficiently convert different types of biomass into charcoal.

Solutions to these challenges involve developing more affordable and versatile pyrolysis units and promoting government subsidies or incentives to encourage the adoption of these technologies.

Supply Chain and Market Development

Establishing a reliable supply chain for biomass feedstocks and developing markets for both the charcoal and by-products like bio-oil and syngas are essential for the economic viability of biomass charcoal production.

Strategies include building partnerships between biomass suppliers, charcoal producers, and end-users, along with creating awareness about the benefits of biomass charcoal to develop demand. The continuous charcoal making machine could process a large capacity biomass waste.

Future Prospects

The future of charcoal from biomass looks promising, with ongoing research and technological advancements improving its production efficiency and applications. Innovations like mobile pyrolysis units could bring production closer to biomass sources, reducing transportation costs and increasing sustainability. Additionally, enhanced understanding and application of biochar in carbon sequestration and soil improvement could play a significant role in combating climate change and promoting sustainable agriculture.

Moreover, integrating biomass charcoal production into existing waste management and agricultural practices could create closed-loop systems that enhance sustainability while providing economic benefits to communities.

Conclusion

Charcoal from biomass represents a pivotal shift towards sustainable energy and material management. Its production and utilization offer a pathway to address environmental concerns such as deforestation, air pollution, and soil degradation, while also providing renewable energy, enhancing waste management, and supporting economic development.

As we move forward, the continued exploration and adoption of biomass charcoal technologies, coupled with supportive policies and community engagement, will be crucial in realizing its full potential. This transition not only heralds a step toward a more sustainable and environmentally friendly future but also underscores the importance of innovation and adaptation in our journey toward sustainable development.