Plastic pyrolysis plants play a crucial role in reducing carbon emissions by addressing the environmental challenges posed by plastic waste. Here’s why:

Waste-to-energy conversion: Plastic pyrolysis involves the thermal decomposition of plastic waste in the absence of oxygen, converting it into useful products such as fuel oil, gas, and char. This process provides an alternative energy source that can replace fossil fuels, thereby reducing greenhouse gas emissions associated with traditional energy production.

Diverting plastic from landfills and incineration: Plastic waste that ends up in landfills or is incinerated contributes to the release of harmful greenhouse gases like methane and carbon dioxide. By diverting plastic waste from these disposal methods, plastic pyrolysis machine prevents the emission of significant amounts of carbon into the atmosphere.

Carbon-neutral fuel production: The fuel oil obtained from plastic pyrolysis can be used as a substitute for conventional fuels like diesel or gasoline. When burned, this fuel releases carbon dioxide, but since the plastic feedstock originated from fossil fuels, the overall carbon footprint remains neutral. By utilizing plastic waste as a feedstock, we avoid extracting additional fossil fuels, indirectly reducing carbon emissions.

Recycling potential: Pyrolysis plants offer a solution for hard-to-recycle plastics that would otherwise accumulate in the environment. Instead of being discarded or shipped to other countries for processing, these plastics can be converted into valuable resources. This reduces the demand for virgin plastics, which require significant energy and emit greenhouse gases during their production.

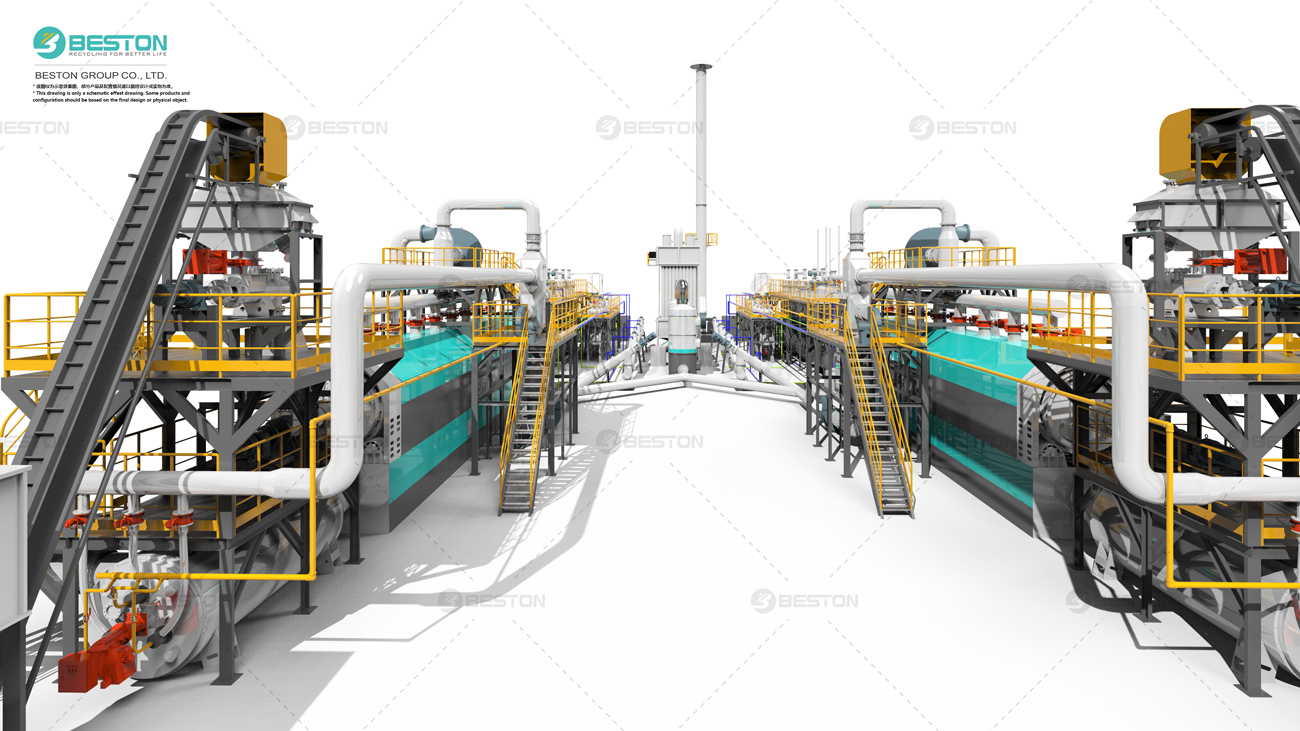

Circular economy approach: Plastic pyrolysis aligns with the principles of a circular economy by transforming waste into usable materials. It promotes resource efficiency and minimizes the need for extracting new raw materials. As a result, pyrolysis equipment for sale helps reduce the overall carbon emissions associated with the extraction, transportation, and manufacturing processes involved in traditional material production.

Methane reduction: Plastic waste in landfills can produce methane, a potent greenhouse gas that contributes to climate change. Plastic cannot be easily recycled through traditional methods. By integrating pyrolysis plants into waste management strategies, we can ensure that plastic waste is properly handled and processed, minimizing its environmental impact. This synergy allows for a more comprehensive approach to waste management, where recycling, reduction, and energy recovery work together to achieve sustainable outcomes.

Encouraging a shift towards a circular economy: Plastic pyrolysis aligns with the principles of a circular economy, which aims to minimize waste generation and maximize resource efficiency. By converting plastic waste into valuable products like fuel oil or gas, pyrolysis plants contribute to closing the material loop. This reduces the need for virgin resources and lowers the carbon emissions associated with extracting, manufacturing, and transporting new materials. When you choose this machine, learn about pyrolysis reactor types.

Sustainable alternative to incineration: Incinerating plastic waste is a common disposal method but comes with environmental drawbacks. Incineration releases harmful pollutants into the atmosphere and can contribute to air pollution. Plastic pyrolysis provides a more sustainable alternative by generating useful products while minimizing harmful emissions. It offers a way to manage plastic waste without resorting to environmentally damaging practices.

Promoting innovation and research: The development and implementation of plastic pyrolysis plants have spurred innovation and research in waste management technologies. Researchers and engineers are continuously working on refining pyrolysis processes, enhancing efficiency, and exploring new applications for the products generated. This ongoing innovation contributes to finding even more effective ways to reduce carbon emissions and address plastic waste challenges.

Global scalability and impact: Plastic waste is a global issue that requires scalable solutions. Plastic pyrolysis plants have the potential for widespread adoption and can be implemented in various regions around the world. By reducing carbon emissions at a significant scale, these plants have the capacity to make a substantial impact on mitigating climate change and tackling the plastic pollution crisis on a global level.

It’s important to note that while plastic pyrolysis plants offer environmental benefits, they should be integrated into a comprehensive waste management system that includes reduction, recycling, and sustainable alternatives to plastics. Additionally, continuous monitoring and regulation are necessary to ensure the proper operation of these facilities and prevent any potential negative impacts on human health or the environment. If is available for you to see this machine on this web: https://www.bestongroup.com/ko/.

While plastic pyrolysis plants offer significant environmental benefits, it’s important to ensure that these facilities adhere to strict emission control measures and operate within legal and regulatory frameworks. Additionally, efforts to reduce plastic consumption, promote recycling, and develop sustainable alternatives should complement the role of pyrolysis plants in mitigating carbon emissions.