The all-new state-of-the-art pyrolysis machine in the Philippines is one of the highly used plants. The plant is known for producing tons of benefits for its owners. If you didn’t already know, there are very strict rules when it comes to the environment in the Philippines.

Whenever waste management efforts are assessed, most persons turn to the green option. As such, the plant from a reputable manufacturer is a great option. Reliable sources tend to produce and sell pyrolysis plant in the Philippines that automatically clean emissions. So, read on as we dive into more on the pyrolysis machine Philippines.

Within the country, there are tons of waste products that can be easily turned into oil via this technology. Additionally, the waste being used is said to be non-degradable, has good elasticity, and can also contract thermally. Tires are the main resource used in these operations.

Since there are so many old tires, they can be easily recycled. In the country, there are bus tires, truck tires, car tires, off-road tires, motorcycle tires, industrial tires, and many more. This makes it readily accessible to process. When you wanna know how much exactly you will spend, click this page – pyrolysis plant price.

Additionally, rubber is also another major product that needs to be recycled. After undergoing recycling, the rubber is converted into oil. However, other sources of rubber such as neoprene rubber, nitrile rubber, natural rubber, silicone rubber, ethylene propylene diene monomer, butyl rubber, and many others can also be processed.

Besides those mentioned, another common everyday product is plastic. Plastic includes the likes of bottles and bags and is found in many applications each day. Just like the others, there are extremely difficult to recycle and require special processing.

Oil sludge is a harmful pollutant that will pollute the air and the soil if it isn’t taken care of. Hence, pyrolysis tech is an exceptional method for recycling engine oil and oil sludge. After processing, pyrolysis oil is produced and has a very high resale value. Take view at this continuous waste tyre pyrolysis plant.

In today’s society, there are continuous developments that are done to make procedures more efficient and this method of recycling is much better when compared to many others. However, some of the other methods such as landfills, and burning tend to have massive tire requirements. In essence, they are very bad for the environment.

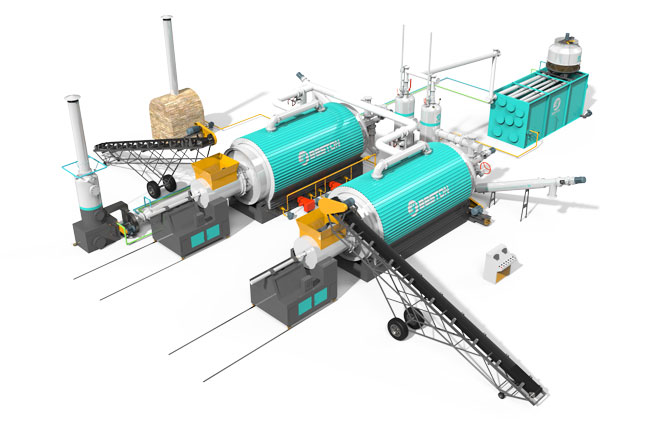

Before purchasing it’s best to look out for a reputable manufacturer. These are those who offer different variations of the processing plant. Some of these include minis, continuous plants, and even batching plants. Each of those would have different specs that meet the different demands that you and others may have.

It should be noted that the smaller plant in the Philippines easily processes up to 10 tons each day. The installation and maintenance on this one are quite simple and suited for small-scale businesses. In the case of the continuous variant, up to 24 tons are processed in a single day. See this tyre oil plant project report and get more information.

The continuous plants usually work for 24 hours each day. However, after about 7 days, maintenance should be done to keep the plant running smoothly. This pyrolysis machine is better suited for larger businesses.

In conclusion, we have just looked at the pyrolysis machine in the Philippines. These machines are great for recycling and they are eco-friendly. So, if you’re interested in a new project, this is a great one for you!